ROTARY SHAFT SEALS

Rotary shaft seals, also known as oil seals or radial shaft seals, are essential components used in rotating machinery to prevent fluid leakage and contamination. They provide a barrier between moving and stationary parts, ensuring efficient operation and extended service life of mechanical systems.

Functions of Rotary Shaft Seals

✔ Prevents Lubricant Leakage – Keeps oil, grease, and other fluids within the system.

✔ Blocks Contaminants – Protects against dirt, dust, water, and other environmental elements.

✔ Reduces Friction & Wear – Minimizes direct metal-to-metal contact between components.

✔ Enhances Equipment Longevity – Prevents premature failure of bearings and other critical parts.

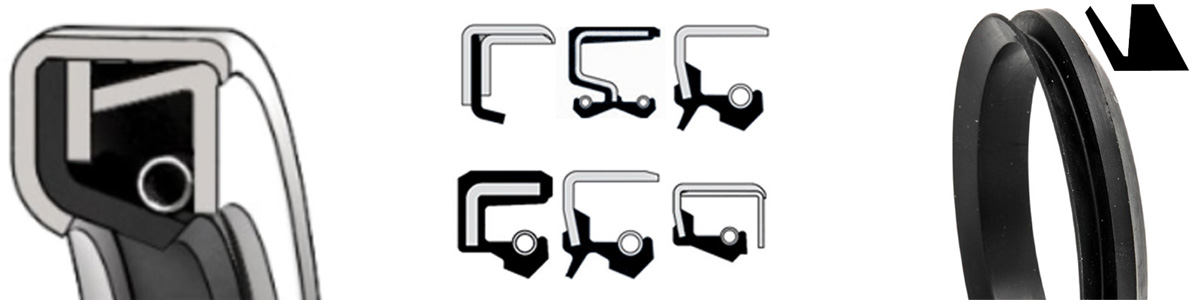

Types of Rotary Shaft Seals

🔹 Single Lip Seals – Used for general applications with moderate lubrication and contamination protection.

🔹 Double Lip Seals – Provide extra protection against contaminants, ideal for harsh environments.

🔹 Spring-Loaded Seals – Maintain consistent sealing pressure, even with shaft movement or misalignment.

🔹 Cassette Seals – Fully enclosed for extreme dirt and moisture conditions, commonly used in off-highway vehicles.

🔹 V-Ring Seals – Flexible rubber seals designed to protect against dirt and dust while allowing axial movement.

Common Applications

🛠 Automotive & Heavy Equipment – Used in engines, transmissions, and wheel hubs.

🛠 Industrial Machinery – Found in pumps, compressors, and gearboxes.

🛠 Agricultural & Construction Equipment – Protects rotating components in tractors, loaders, and excavators.

🛠 Aerospace & Marine – Used in turbines, propeller shafts, and hydraulic systems.

Materials Used

🟢 Nitrile Rubber (NBR) – Good oil resistance and cost-effective.

🟠 Fluoroelastomer (FKM/Viton®) – High heat and chemical resistance.

🔵 Silicone – Performs well in extreme temperatures.

🟣 PTFE (Teflon®) – Suitable for high-speed and dry-running applications.